You might already know how magical RFID tags have. RFID tags provide us with a more intelligent and convenient way of life. They apply in various industries and revolutionize many industries. But RFID tags are prone to interference by water or metal, especially UHF RFID labels. If you want to use it in applications on the metal surface, there are a few things you must know.

1、Why Are RFID Tags Prone To Metal Interference?

It is well known that RFID tags transmit information through radio frequency signals. But UHF signals are easily reflected by metals and absorbed by water. For instance, our body is an excellent barrier to RF signals because there is plenty of water in our bodies. And when you use ordinary RFID tags to manage IT assets, they may not work because of metal interference. Why?

RFID reader antenna has the function of absorbing the energy of RF. But the metal will cause eddy currents around RFID readers, thus reducing the efficiency of the RFID electromagnetic field. These eddy currents also cause their own magnetic fields perpendicular to the surface of the metal. And these vertical magnetic fields will invalidate the reader area.

Besides, metal can also cause extra parasitic capacitance. That can cause detuning of RFID readers and electronic tag antennas, and undermine system performance. Eventually, in some wavebands, the electrons reflected by the metal will interfere with RFID tags and RFID readers.

Therefore, when RFID tags are used in applications where has many metal materials, the RF performance will be greatly reduced. Although it is a great challenge for RFID applications, there are some good solutions, such as anti-metal tags.

2、What is an RFID Anti-metal Tag?

The Anti-metal label is specially designed for complex environments such as metal. Based on the traditional metal label, a special anti-metal material is added to make it work well on the metal surface.

RFID anti-metal tags feature long reading distance, high sensitivity, heat-resisting, strong physical properties. They are very suitable for various metal environments, such as medical equipment management. The main features are as follows.

- Not only is it has strong metal resistance, but it can also withstand high temperature(up to 200 ℃) as well as mechanical impact and strong vibration.

- Strong resistance to chemical substances, such as hydrochloric acid and sulfuric acid. RoHS certified products will have a stronger protection level than other similar products.

- It has stable performance even works in extreme environments such as high-temperature applications.

- Meet international standards, such as ISO15693 and ISO18000-3, etc.

- Good reading performance, even farther than the distance read in the air.

- High protection level up to IP63, some UHF anti-metal labels can reach IP68.

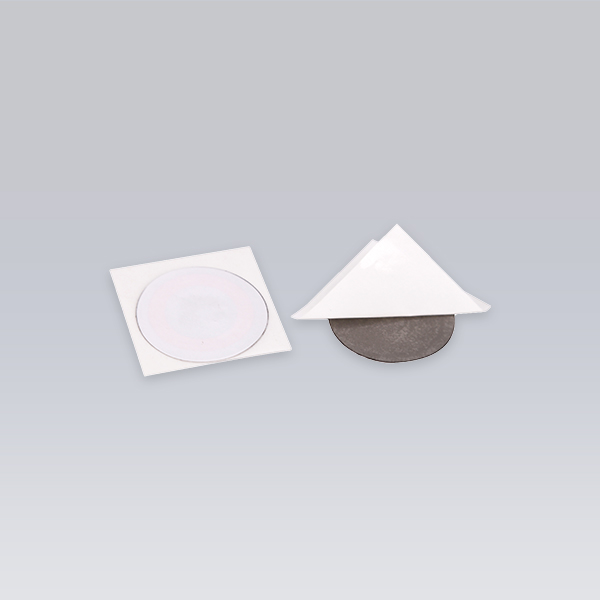

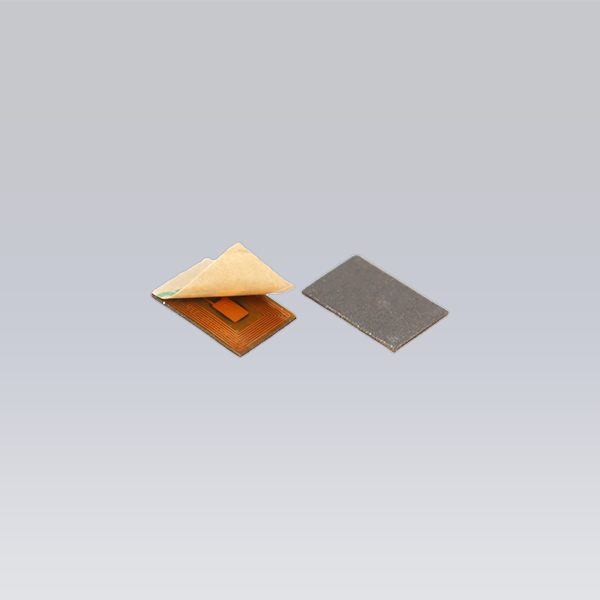

3、What Are The Common RFID Anti-metal Labels?

Common anti-metal labels mainly include ABS, PCB, Epoxy, ceramics, etc. They always work on 13.56 MHz or 860~960 MHz. RFID anti-metal tags can be made into various styles and shapes, such as bar, square, and round. Here are some Xinyetong RFID Anti-metal Tags, if you want to learn more, feel free to contact us.

Each anti-metal label has distinct characteristics. ABS anti-metal labels are packaged with ABS engineering plastic. It has the characteristics of sunscreen, waterproof, and high-temperature resistance, etc.

PCB and FPCB anti-metal tags can be small sizes, suitable for tool management and small electronic devices tracking. Anti-metal stickers and epoxy anti-metal tags are low cost. They are very suitable for large quantities and limited budget applications.

Flexible metal labels can be bent and fit sticking to uneven surfaces, like metal cylinders, etc. Ceramic labels can not only work on metal surfaces but also prevent transfer and removal. It is suitable for anti-counterfeiting traceability applications.

4、What Applications Do Anti-metal Labels Apply?

Anti-metal tag solves the problem that RFID is vulnerable to interference. It has attracted much attention since birth and has been favored by various industries. It is widely used in asset management, medical device management, and so on. Common usage scenarios are as follows:

- Warehouse asset management: shelf identification, metal asset management, etc.

- Indoor equipment management: follow-up of household equipment products, company fixed assets management, etc.

- IT asset management: computer mainframe, switch, server chassis, aluminum bar, etc.

- Sheet metal management: plate classification, management, and tracking, etc.

- Medical device management: large medical instruments, surgical instruments, etc.

- Outdoor asset management: power equipment, IT assets, pressure vessels, cylinders, etc.

- Tooling production line management: parts process management, tools management, pallet management, etc.

- Logistics management: truck tracking, cargo tracking, etc.

5、How to Choose Anti-metal Tags?

How to choose appropriate RFID anti-tags for your application? This is a question that often makes people confused. Choosing a label in a particular application, we must consider many factors, such as the price of the label, physical size, material, and shape, etc.

However, more attention should be paid to the factors that will affect the performance of tags. For example: what is the read-write distance of the label? What is the material of labels and the mounting surface? How to install? What about the application environment?

If you think RFID anti-metal tags are only required when used on the surface of the metal, you must change your mind. Because the label is not directly affixed to the metal does not mean that it will not be disturbed by the metal. If there is a lot of metal around where RFID tags are installed, RFID tags are also prone to interference.

So, choosing RFID anti-metal labels, we must carefully judge to ensure that the performance of tags is stable and reliable. If you also do not know how to choose RFID tags, feel free to contact us. All Xinyetong professional staffs are at service for you.